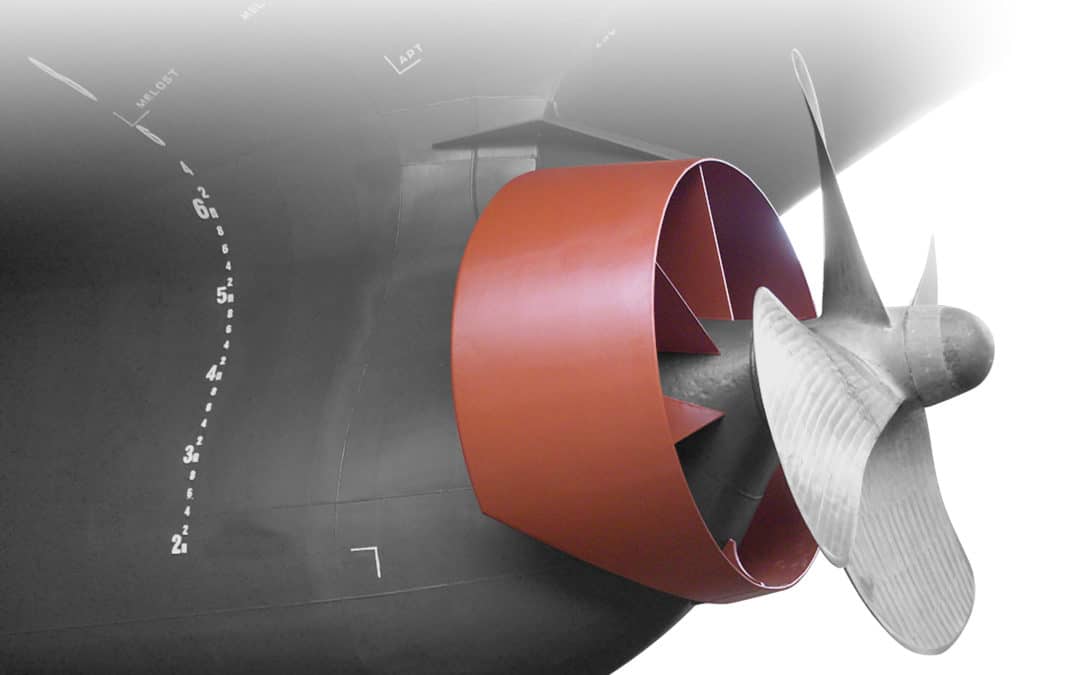

Since its introduction in 2008, the Becker Mewis Duct has been successfully improving efficiency and reducing emissions for ships. Here’s a look at its impact over the past decade.

What is the Becker Mewis Duct?

Within ten years, the Becker Mewis Duct® has become a globally successful product. Demand for the energy-saving device is rising again as the new IMO environmental guidelines come into force next year. Accordingly, there will be great interest at the Nor-Shipping trade fair taking place in Oslo from 4th to 7th June 2019. Becker Marine Systems will also present other manoeuvring systems and energy saving solutions for ships.

Impact on the shipping industry

Well over 1,000 units of the Becker Mewis Duct® have been sold to date, for both newbuildings and retrofits.

Worldwide, emissions of CO2 have been lowered by more than seven million tonnes by employing the energy saving

duct. “Our company has written a success story with this product,” says Dirk Lehmann, Managing

Director of Becker Marine Systems, “and demand continues to grow unabated”.

One reason for this is the stricter environmental regulations of the International Maritime Organization (IMO).

According to the IMO 2020 regulation, starting 1st January 2020, vessels may only operate on the high seas with

fuel that has a maximum sulphur content of 0.5 per cent instead of the previous 3.5 per cent. For the shipping

industry, this means considerable additional costs, which can be reduced by lower energy consumption.

“By employing the Becker Mewis Duct®, consumption is lowered by an average of six per cent for both empty

and fully loaded ships,” says Lehmann, “reductions are often higher for older ships.” For this reason, many

owners are taking advantage of the opportunity to upgrade their ships to the state of the art by retrofitting.

“Delivery time is currently around three months, plus one week for retrofitting at a shipyard,” says the Managing

Director of the ship supplier.

This means that there is enough time to react to the IMO 2020 regulation and to reduce the rising costs for

fuel through the efficient use of the Becker Mewis Duct®. The same applies to the guidelines relating to the

Energy Efficiency Design Index (EEDI). Here too, the Becker Mewis Duct® is a tried and tested way of lowering

CO2 emissions and enabling more sustainable shipping.

“By the combination of reducing additional costs and at the same time acting in a more environmentally

friendly way, we expect a further increase in interest in the duct at our exhibition stand in Oslo”, commented

Lehmann on the forthcoming Nor-Shipping, one of the world‘s most important trade fairs for the maritime

industry. The Becker Mewis Duct® Twisted is currently being used for large 22,800 TEU container ships built-in

China for French shipping company CMA CGM.