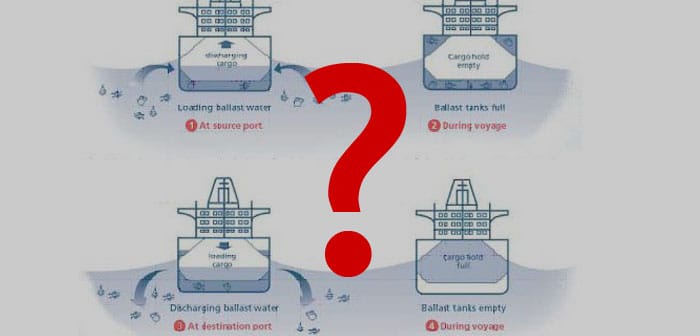

As the original deadline for Ballast Water Management systems passes, we present a selection of views from different sides of the industry. Uncertainties persist about – to name a few – the effectiveness and durability of systems, suitability of systems for different ships, production capacity of manufacturers, the installation capacity of yards, sampling procedures, and maintenance requirements.

Even with an effective two-year extension to the IMO’s deadline, is installation of working units even possible across the world’s fleet?

Susanna Wyllie, Global Proposals Manager – BALPURE® at De Nora:

“It is extremely disappointing that the IMO has accepted the proposal of these member states to push compliance with the BWMC convention two years further out and retain its link to the International Oil Pollution Prevention Certificate (IOPPC) issued every five years.

“Two years may not sound like a long extension, but with many owners choosing to renew their five-year IOPPC on the cusp of entry into force the reality is that this pushes industry compliance out by up to seven years. This brings the adoption of the convention, a clear recognition of the damage being done by invasive species and the need to tackle it, and industry-wide compliance with the environmental protection practices the IMO deemed necessary to 20 years.

“Over 50 ballast water treatment systems have IMO Type Approval. Several systems already have USCG approval with many more, including BALPURE, going through the approval process and certified under the USCG AMS. It is evident that the industry is well prepared to meet the entry into force deadline with full compliance.

“As the IMO has now made it clear that compliance with the convention is required from the next IOPPC date after September 2019, we hope that we will see significantly more preparation from owners and operators in the next two years than we have seen in the 13 years since the adoption of the convention.”

Ian Stentiford, Evoqua’s Global Vice President, Electrochlorination:

“We deliberately selected an independent laboratory that would challenge the SeaCURE system as part of the whole approval process. The testing NSF partners carry out is extensive and places considerable demands on the system in real-life, operational conditions. Testing uses real organisms, in different salinities, different water temperatures and different local environments, taking into account organism regrowth.

“It is very stringent; but we knew that if the SeaCURE system could pass these tests, then shipowners will be confident that the system they have invested in is very robust and it can actually do what it has been designed for in all at-sea operating conditions encountered.”

A view from Intercargo:

“INTERCARGO welcomes and supports the Ballast Water Management (BWM) international initiatives and legislation however, it should be recognised that the implementation needs to be made in the most effective and practical manner possible. A newbuilding vessel case is totally different than retrofitting an existing vessel, while a bulker carrier is also a different case than other types of ships.

“Finally there are concerns regarding the production capacity and availability of service engineers of the approved systems manufacturers. Will they be able to meet the required demand for fitting these systems both for new build and for the existing fleet? The lack of experience with these systems cannot be underestimated. It is not known how these systems will perform in the future and whether they will be able to meet the requirements leading to potential extra burdens for the ship owners. It is only now becoming fully clear to ship owners how complex and onerous the requirements are for bulk carriers that need to be retrofitted with approved BWTS.”

Ioannis Stefanou BEng (Hons), MSc, CEng, MIMarEST, Group Technical Director at Wallem Shipmanagement:

“Within the Wallem-managed fleet we have more than 40 vessels with BWTS installed; either during the New Building stage or retrofitted. These are systems across the range of five different treatment technologies and by various manufacturers. Only two thirds of the systems installed were fully operational onboard within the first six months – on some vessels they were not fully operational even after a year. The problems weren’t inherent to a specific type of technology or manufacturer; although I have to mention that one type of technology had a 100% success rate for problem-free operations, despite different manufacturers. I don’t have any official numbers from the industry but it is understood from informal chats that issues with the installed systems is something commonly experienced.

“At Wallem, when we realised the extend of the challenges that the crew and the Superintendents faced with the operation of some of the BWTS, we decided to follow a centralised approach and have one person focusing on making sure that the systems onboard had become fully operational, before handing over responsibility to the Fleet Superintendents.”

Anders Lindmark:

“Alfa Laval has been a supplier to the marine industry for 100 years and we will continue to be a supplier also of BWTS going forward. Important in this case is that the IMO BWM Convention is ratified and will enter into force and that we have clarity of the implementation schedule for D-2 compliance. We also have the fact that D-1 compliance will be mandatory from September 2017 and that the requirements related to discharge in US waters are already in force, which needs to be taken into consideration. We will continue the close cooperation we have with our customers to find the best solutions for their fleets for the coming two years and also for the period from September 2019.

“We have for the last years prepared the different parts of our organization for the increased demand driven by the BWTS retrofit market and are well prepared. This includes resources for sales, technical specialists, project management, service and manufacturing. We are well prepared to support our customers with the execution of their BWTS projects and also with long term service of the systems, through the global Alfa Laval service network.”

Marc Raymond, Managing Director, aqua-tools”

“While much focus has been given to the ballast water treatment system, there has been little discussion about enforcement,” said Bonamin. “Existing ballast water testing methods could mean that incorrect measurements are taken, resulting in heavy financial penalties for shipowners. We now have the technology available to provide 100% indicative but accurate readings more or less immediately, without having to send samples off to laboratories.

“We have developed a unique method for extracting the ATP from the cell walls of all marine organisms, including those with hard shells, in a process that takes just five minutes. Our method analyses each fraction: >50µm (most often zooplankton), 10-50µm (most often phytoplankton) and bacteria, which other ballast water monitoring systems struggle to achieve.”

.