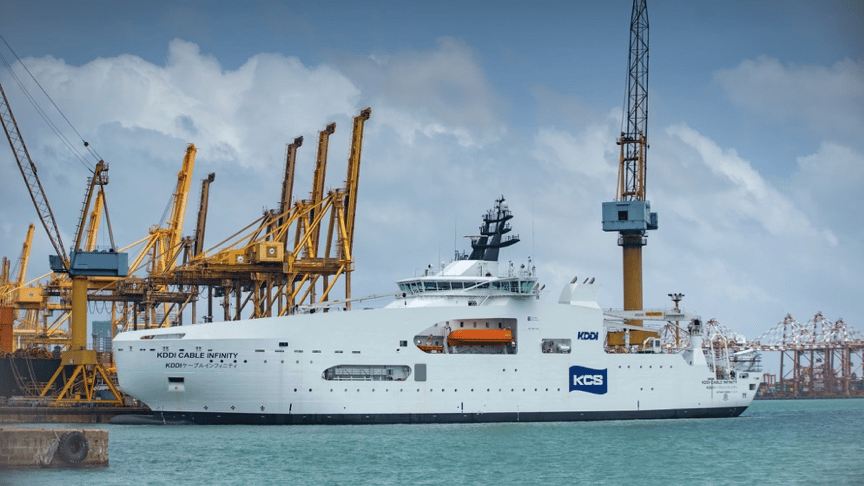

Colombo Dockyard has delivered a modern Cable Laying Vessel to Kokusai Cable Ship Co. Ltd. (KCS). The vessel is the first to be built ‘in its class’ by a Sri Lankan company for a Japanese owner. After leaving the Colombo Dockyard, KDDI Cable Infinity successfully reached the Yokohama port, Japan on July 7, 2019.

At 113.1 meters in length, 21.5 meters in breadth and 8.8 meters in depth, KDDI Cable Infinity is the largest vessel constructed by Colombo Dockyard to-date. KDDI Cable Infinity has a deadweight carrying capacity of 5,757 DWT at a maximum load laying draught of 7.1 meters. It hosts accommodation facilities for 80 persons and has a speed of 14.5 knots.

The basic design and detailed drawings for the construction of KDDI Cable Infinity were supplied by VARD Designs, Norway and were tailored to ensure the maintenance of good sea keeping ability and excellent station keeping performance.

Built for worldwide, subsea operation to ClassNK classification society standards and JG requirements, the vessel will undertake cable installation and repair works of optical and power cables. For the handling of power cables, the vessel’s forward tank has been fitted with a carousel system with a payload capacity of 2000 tons, a loading arm and a control cabin.

The vessel is diesel electric-driven and has optimised power provided by four generator sets, each generating 2,300Kw. Three out of the four generators on board are sufficient to cope with the highest propulsion power demands, ensuring high reliability with a bollard pull of up to 80tons. Fuel consumption during transit is optimised by the running of two generator engines efficiently and the vessel is equipped with Dynamic Positioning capability to Class 2 for precision maneuvering and station keeping. Propulsion is achieved through two azimuth propellers in the aft and two tunnel thrusters and one retractable azimuth thruster in the forward. All five thrusters on board the vessel are controllable pitch propelled with variable RPM. This enables the pitch and RPM to be optimised to give the best fuel economy.

KDDI Cable Infinity has been designed with low resistance hull lines for higher speed and low fuel consumption. The vessel is also equipped with a scrubber and SCR technology to reduce harmful emissions to comply with IMO Global Sulphur Cap 2020 requirements. Special attention has been paid to maintain noise and vibration levels in the accommodation and working spaces in accordance with IMO requirements, providing greater comfort and a better working environment for the personnel onboard.

Two electric-driven, self-fleeting Drum Cable Engines, both 4 meters in diameter, enable a haul-in capacity of 40tons. Each of the four-wheel, paired Draw Off Hold Back (DOHB) linear cable engines are also electric-driven with synchronised drive systems.

KDDI Cable Infinity is equipped with tension slow down features integrated in to the DP system so that if the laying cable tension is too high, vessel speed will be reduced as a safety feature. An “A-Frame” of 50-ton capacity for ‘plough’ deployment and recovery over the stern is installed on the vessel in addition to Buoy Handling “A Frames” and an ROV “A Frame”.

“The delivery of this modern-day highly sophisticated Cable Laying Vessel is testament to the pride and dedication exhibited by Colombo Dockyard’s shipbuilding team. It demonstrates Colombo Dockyard’s proven capability to design, construct and deliver large, complex vessels to international markets as well as domestic market.” Says Mr. D.V. Abeysinghe MD/CEO of Colombo Dockyard